The New Face of a Freelance Traction Engine

In December 2017 an opportunity arose to purchase a freelance traction which is based on the popular 1” scale “Minnie” design but increased in size to 3 ½” scale.

The engine was originally built in the 1980’s and registered for the road in 1987, who actually made it is unknown but if you know please get in touch.

It is fair to say that the engine was obviously built on a shoe string and has the appearance of being built during lunchtimes at work! The Engineering leaves a lot to be desired but having said that it has stood the test of time and although seen better days it has been running for 30 years!

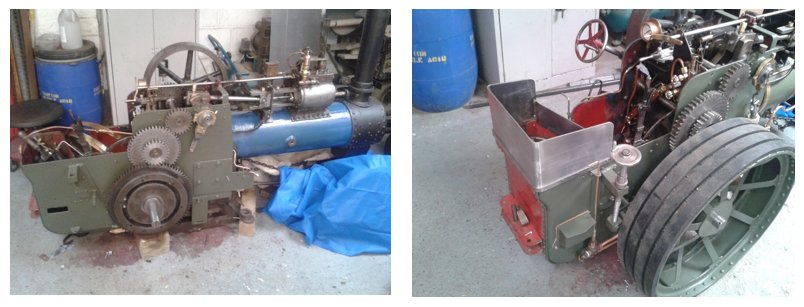

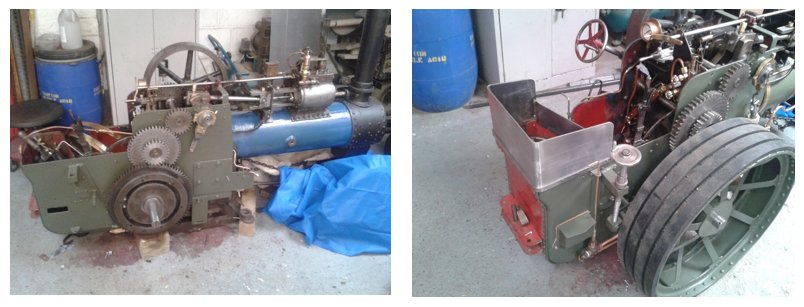

When viewing the engine with a mind to buying it you had to look past the rough exterior and imagine what it could be with a bit of work. With that in mind a price was agreed and the engine was collected on 1st January 2018. The following pictures show what a state the engine had become.

Although the engine came with a boiler certificate the initial job was to ensure the boiler was safe but before any testing could be done it required a very thorough clean. We got almost a bucket of scale and loose rust from inside the boiler then using an endoscope checked the interior of the boiler for signs of corrosion. fter that the material thicknesses were measured using an ultrasonic thickness tester and the boiler appeared safe to perform a hydraulic test. Because the boiler was unknown to us and old it was decided to test the boiler to twice the safe working pressure and all was good with no signs of leaks or distortion. A trial fit of the grate and ashpan found that it didn’t fit so a couple of hours were spent modifying that, it will be replaced later to give better control of the airflow and allow ash to naturally clear.

The following weekend and after ensuring all the steam fittings were serviceable the fire was lit and within an hour the safety valves were lifting. A quick run up and down the drive proved that there were a few issues so during the following week a new piston was made along with a new rod and then fitted to newly aligned slide bars. Another trial run over the next weekend found that 4 teeth were missing from the final drive gears which needed repair because now the engine was unusable.

During our first run there was a strange noise and the engine tended to “wobble”, this was found to be the rear wheels and all the screws securing the spokes had sheared off! How the wheels didn’t collapse is a miracle! The front wheels also received some attention to make them more presentable and having the centre bored out to be able to fit a bronze bearing. Removing the old rubber tyres revealed many unused holes that presumably were drilled to secure previous tyres, in all about 50 extra holes were in each wheel so they were welded up.

A Company that specialises in cast iron welding was used to build up the area of damage on the large gear and then new teeth were cut. The mating gear was found to be available from stock and only required a bit of modification to fit. During the time when the gear was away being welded various other parts were being repaired, the list of things to do was very long! Corrosion had set in around the front of the smokebox and it was so bad that the smokebox ring had separated from the smokebox by ¼” and the gap filled with car body filler! Needless to say the fit of the smokebox door was very poor and how it sealed enough to allow the boiler to make steam we will never know.

Over the coming weeks nearly all the pipework was replaced, an enormous hand pump on the footplate was removed and an injector fitted, also the mechanical pump was rebuilt. Attention was then paid to the gear train, shafts and bearings. All of the bearings were found to be badly worn and so all were replaced and adjustments were made to correct the gear meshing. Now with the gears meshing correctly a new gear guard was made to replace the hideous one that came with the engine.

The next big challenge was to repair the rear wheels, they had been fabricated using all sorts of “odd ends” and then fitted with the tread from car tyres! A good idea but certainly didn’t help the looks of the engine. The tyres were not quite the right diameter so a piece of lino had been packed under the tyre to fill the gap! Now with the spokes secured and welding in place the wheels were finished off with some new rivets, a bit of filler and a fresh coat of paint.

Initially the plan was to make the engine safe and useable but we got a little carried away! An offer of NATO green paint seemed a good idea and simply paint all of it to make it more presentable and of course very appropriate if it carried the War Department markings being the 100th anniversary of the end of WW1.

As bits got removed, repaired or replaced and then painted the engine started to look like a Traction Engine again the original red paint (and some old blue) slowly disappeared. Now we could start to make a few additional improvements like a new brake handle and bunker extension.

Towards the end of April the engine was really looking good and the time had come to fit some new tyres to the rear wheels. A friend had a source of rubber strips which looked suitable with 4 of them on each wheel also with the offer of some car windscreen adhesive they were fitted to the wheels. Each wheel took about an hour to do but really makes a big difference to the appearance.

With a bit more paint and some sign writing the engine was ready for a steam test which it passed with flying colours. There is still a few jobs to do like replacing the steering wheel and gear mechanism and over the next winter the valve gear will receive some more attention but with summer on the way (hopefully) the engine will now get some use.

This is what it looked like on the day of the steam test which is a remarkable improvement from 4 months ago.

And a couple of pictures below of Minnie on it’s first road run to a local pub with a 4” scale Fowler, a trip of about 7 miles in total. Happily no issues occurred with the engine apart from driver error by enjoying our meal and drink too much and neglecting the fires!